Valves for dams, reservoirs and hydropower

The AVK Group offers a comprehensive selection of high-quality discharge control valves and guard valves of our own manufacture, along with a wide range of other valve types from our own brands and selected trusted partners.

AVK is a world leading manufacturer of valves for the water industry, and several of our companies have particular expertise in the specialised valves and gates used in dams, reservoirs and hydropower infrastructure projects. Orbinox has a proven track record of delivering tailor-made solutions to a wide range of projects across the globe over the past 40 years. Glenfield contributes with more than a century of expertise in this segment with one of their earliest projects dating back to 1913, and today their highly durable designs are manufactured at our high-tech large valve facility in China. AC.MO adds a wide selection of needle valves and AVK’s large range of products for water supply complement the range.

Below please find a short description of our own manufactured products including links to our product finder comprising datasheets for each product.

- Discharge control valves: fixed cone and submerged discharge valves, and needle valves

- Radial gates

- Roller gates

- Stop logs and gates

- Penstocks

- Guard valves: butterfly valves, knife gate valves, bonneted gate valves and gate valves

- Check valves: tilting disc check valves and recoil check valves

- Regulating valves: needle valves and ball float valves

- Air valves

- Dismantling joints

Please also find links to our brochure, animations and case stories at the bottom of this page.

Discharge control valves

Discharge control valves are designed to both regulate the discharge flow from dams and reservoirs and hydro by-pass systems and safely dissipate the immense kinetic energy contained in large amounts of rapidly flowing water.

Fixed cone (free) discharge valves discharge a hollow shaped jet of water directly into the atmosphere. Submerged discharge valves discharge sub-surface jet underwater into a sump/stilling basin. Needle valves are typically used as ‘inline’ control valves but can also be used to discharge to atmosphere. All three types of valves can be used for closing off or regulating bottom and intermediate water outlets of dams and reservoirs, as well as in hydroelectric turbine bypass systems.

All three valve types are efficient, robust and proven by decades of service - making them key components in dams, reservoirs and other critical water infrastructure around the world.

Fixed cone (free) discharge valves

Fixed cone valves are simple, light-weight discharge control valves that release a hollow cone shaped jet (fan or spray). The valves are therefore also known as hollow jet valves and jet disperse valves. They are also known as sleeve valves as well as Howell-Bunger valves, named after Mr. Howell and Mr. Bunger, who developed a fixed cone valve design in the 1930’s. As the valves are discharging directly to atmosphere, any cavitation occurs in the air without damaging the valve, and the kinetic energy in the water is absorbed and dissipated against the ambient atmospheric pressure, before it falls like a heavy rain or is directed by a ‘hood’ in the form of a jet into a downstream ‘stilling pond’. Fixed cone valves are linear control valves that can operate at any percentage (>10%) open, making them excellent for regulation, and the release of environmental flows. Fixed cone valves are also able to handle much higher velocities/flow rates (up to 25 mps) than other types of control valves, meaning that they can be sized smaller than alternatives to meet any given flow rate, do not require to be housed in a valve chamber and are very easy to operate and maintain.

ORBINOX fabricated fixed cone discharge valves type CH can be adjusted to meet the specific service conditions of each application. Sizes up to DN3000 and designs for heads of up to 400mWc in carbon steel or various grades of stainless steel are available with manual, electric or hydraulic actuation. Please see animation at the bottom of this page explaining the function.

→ Series 1425 fabricated fixed cone discharge valves, type CH

AVK series 857 fixed cone discharge valves (Glenfield design) are designed around a single-piece casted body of ductile iron for high rigidity and a sleeve of acid-proof stainless steel with epoxy coated ductile iron components for high corrosion resistance. This standard PN16 design is available in DN200-2200 with manual gearbox, electric or hydraulic actuation.

→ Series 857 cast fixed cone discharge valves

Submerged discharge valves

AVK submerged discharge valves (Glenfield design) provide discharge control within a very compact footprint, with a safe, much quieter and environmentally friendly energy dissipation. The valves are cast in ductile iron and designed with bronze ported epoxy coated body, with stainless steel inner parts for high corrosion resistance. They are available in DN200-1600 in PN16 and DN600-1000 in PN25 and with electric actuator or gearbox.

→ Series 856 submerged discharge valves

Needle valves (also known as ring needle valves and plunger valves)

AC.MO needle valves are designed for the inline throttling and control of pressure and flow at moderate flow rates and high differential pressures. They can also be used as discharge control valves discharging to atmosphere but are limited to flow rates of up to 10 mps and do not dissipate energy – they produce a concentrated jet perfect for shooting along a pipeline or conduit. Needle valves are ideal for constant inline regulation of the flow from intermediate outlets into fishways, irrigation systems or pipelines leading to water treatment plants etc. They are available up to DN2500 and up to PN40 in smaller sizes. Sizes up to DN150 are made of stainless steel as standard, and larger sizes cast in ductile iron coated with fusion bonded epoxy.

→ Series 872 needle valves

Radial gates

Radial gates are typically installed in channels and in dam spillways as control elements for water levels or as regulation and discharge components in bottom outlets. Radial gates consist of a mechanically welded, curved sector-shaped panel that seals using elastomer profiles attached to the panel and interfacing with fixed parts embedded in the concrete structure. It requires only minimal movement to open or close the gate, resulting in low lifting force requirements. The advantages include rapid actuation, high discharge capacity, and safe, straightforward operation.

ORBINOX radial gates type CT are made of carbon steel and are designed for the specific service conditions of each application. Gates used in channels and dam spillways are watertight on 3 sides (sides and bottom) and designed to support overspills if needed, supporting water loads equal to the maximum gate height plus the specified overspill in each case. Gates used as regulation and discharge elements for deepwater dam outlets are watertight on 4 sides and designed for water loads up to 100 mWc.

→ Series 1428 radial gates, type CT

Roller gates

Roller gates are normally used to shut off large openings and high water loads. They are commonly used in water intake towers, dam inlets, and as protection mechanisms at hydraulic power stations where they also can be used as a regulation mechanism for the turbine connection with the network. The gate consists of a strong reinforced fabricated structure, guided by a side roller system that reduces operational loads.

ORBINOX roller gates are made of carbon steel (or stainless steel) and are designed for the specific service conditions of each application. They are capable of supporting water loads of up to 100 mWc and are available with hydraulic or electric actuator.

→ Series 1429 roller gates, type MV

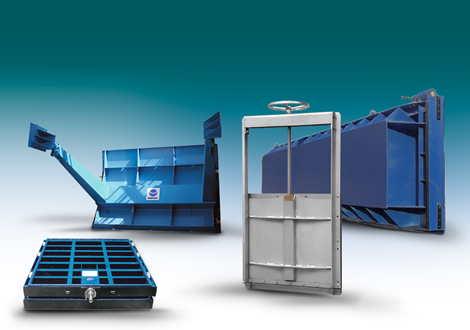

Stop logs and gates

Stop logs are modular, removable barriers used to control water flow in hydraulic structures such as dams, reservoirs, spillways, and hydroelectric plants. Typically made of aluminium or steel, stop logs are stacked vertically within guide slots embedded in concrete walls or piers. Their primary function is to temporarily block or divert water, enabling maintenance, inspection, or operational adjustments without the need for permanent gates or valves.

ORBINOX stop logs are designed for open channel installations in waste treatment plants, irrigation, hydraulic works and hydro-electric power plants. The slide is formed by several logs that fit on top of each other in the frame. By adding or removing logs, the user can control the flow in a channel. The sealing system is incorporated on both laterals and bottom area of each log, resulting in a watertight seal. The frame is typically embedded in concrete but can also be designed to be wall mounted or face mounted in an existing channel. ORBINOX stop logs type SL are made of stainless steel, while stop logs type SA are made of aluminium. Furthermore, stop gates (type AG) are available on request.

→ Series 772/83 stop logs, type SL

Penstocks

Penstocks are designed to isolate and control flow in pipelines, channels, and reservoirs. They are commonly used in water/wastewater treatment plants but are also widely used in flood control and irrigation systems, as they provide reliable and cost-effective isolation and regulation of flows.

ORBINOX penstocks are fabricated in either steel or stainless steel and built for durability in harsh environments and feature low leakage rates, a heavy-duty construction and a modular design enabling easy customization. The self-adjusting seal design provides easy operation. Manual, electric, or hydraulic actuation is available. Their wall penstocks are of square or rectangular design with sealing on all four sides and are bi-directional up to 1200x1200 mm. Round and rectangular swing flap gate penstocks are also part of their range.

→ Series 772/6X wall penstocks, type MU

Guard valves

Guard valves are high velocity emergency closure & maintenance valves installed upstream of discharge control valves. These valves serve as primary isolation devices, designed to shut off water flow in large-diameter pipelines, penstocks, and intake structures for either emergencies to ensure operational safety or to facilitate maintenance of downstream equipment.

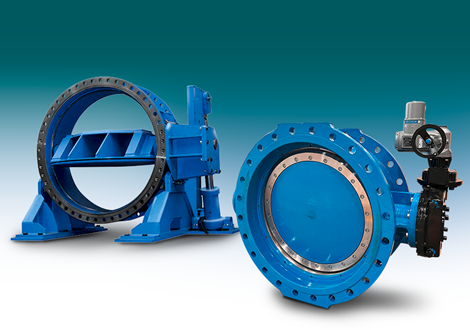

Butterfly valves

Butterfly valves are widely used in dams, reservoirs and hydropower installations. Their compact design and ¼ turn operation make them cost efficient and ideal for installation where space is limited and fast shut-off is required. We offer an extensive range comprising fabricated and cast double eccentric butterfly valves tailored to meet the demands of high pressure/velocity and large diameter applications in water infrastructure.

ORBINOX double eccentric butterfly valves type MB are designed for the specific service conditions supporting liquid speeds of up to 10 m/s for use as penstock protection valves and main inlet valves at hydropower plants, as well as guard valves/emergency shut-off valves typically installed upstream of discharge control valves in dams and reservoirs outlets. They can be made up to DN3500 in many material configurations matching the specific requirements, and with hydraulic, electric or manual actuation.

→ Series 1427 fabricated double eccentric butterfly valves, type MB

AVK double eccentric butterfly valves are designed for shut-off in water applications and are available up to DN3200 and for pressure ratings up to PN25. The slightly tilted disc, optimized seal design, unique shaft pin design and the corrosion protected shaft end zones are all features that exceed the market standards.

→ Series 756 cast double eccentric butterfly valves

Knife gate valves for high pressure/high velocity closure

High pressure knife gate valves, also known as bonneted slide gates, are ideal for large-diameter pipelines where high flow volumes and velocities must be precisely controlled. They are especially effective for media with suspended solids, making them well-suited for dams, reservoirs, and similar applications. The straight-through design ensures minimal pressure drop, while their compact construction offers low operating torque and easy installation - ideal for large-scale infrastructure projects.

ORBINOX fabricated knife gate valves type WS are available up to DN4000. They feature a machined gate with a sharpened edge for full tightness under demanding flow conditions. Designs are tailored to specific pressure, temperature, and velocity requirements. Various configurations are available for materials, sealing systems, flange standards, actuators, and coatings to ensure optimal performance and durability.

→ Series 1432 fabricated knife gate valves, type WS

ORBINOX cast knife gate valves type CW are available in DN80-1000 (bigger sizes on request), and up to PN100 depending on size. They are uni-directional with features and configurations like the fabricated versions.

→ Series 1431 cast knife gate valves, type CW

Bonneted gate valves

A common high dam bottom outlet configuration utilises two bonneted gates installed close together in series. The downstream valve is the working/service valve, with the upstream safety/maintenance valve used only for maintaining the downstream valve. Bonneted gate valves are designed with a rectangular port geometry with a flat metal sealing surface at the bottom. The gate is fully supported all the way down enabling it to close safely into extreme velocities, and to ensure that any debris is flushed through the valve without becoming stuck and preventing its closure. Bonneted gate valves are generally located at bottom or mid-bottom water outlet conduits, with their bodies and bonnets up to their top flange embedded in concrete for extra strength. Due to their size and weight of the gate, they are usually hydraulically operated.

ORBINOX bonneted gate valves are designed for the specific service conditions of each application and are available in sizes up to 2500 x 3500 mm supporting water loads of up to 200 mWc and speeds more than 35 m/s. They are made of carbon steel or stainless steel with bronze rims and moving parts of stainless steel and are normally actuated with a hydraulic actuator due the high stress required.

→ Series 1426 bonneted gate valves, type BU

Gate valves (wedge design)

Gate valves play a critical role in water infrastructure such as dams, reservoirs and hydropower plants by ensuring reliable shut-off of large water volumes under high pressure. Designed for infrequent on-off operation, they offer minimal flow resistance when fully open due to the full bore, making them ideal for isolation duties.

AVK metal seated gate valves (Glenfield design) are available up to up to DN2200 in PN10 & 16 and DN1200 in PN25 & 40 and designed for reliable high-strength performance in large diameter water pipelines. Its metal-to-metal sealing makes it ideal for raw water applications. A special ‘Reservoir Spec’ version of the S54 (S54-41) has been developed for use in dams, reservoir & and hydropower applications, where the ability to close reliably into higher velocity flows of up to 9 mps is critical.

→ Series 54 reservoir specification metal seated gate valves (download brochure)

AVK resilient seated gate valves are made of ductile iron with GSK approved epoxy coating and a wedge fully encapsulated in rubber offering 100% tightness and corrosion protection, ideal for water supply and reservoir systems up to DN1200, and as bypass valves.

→ Series 06 resilient seated gate valves

Check valves

Check valves are essential in protecting water infrastructure from reverse flow, pressure surges and pump damage during shutdowns. The robust design, low maintenance needs and available configurations make our check valves ideal for high-capacity installations.

Tilting disc check valves

ORBINOX tilting disc check valves type RA are double eccentric with wafer or flange connection and cast or fabricated carbon /stainless steel body, available up to DN1600 for applications up to PN16, and for horizontal and vertical installations. They are designed with an external counterweight assembly to help initiate closing when normal flow stops and before there is reverse flow. A hydraulic damping system controls closing velocity and prevents any water hammer in the pipelines. The check valves are ideal for rapid, non-slamming protection against reverse flow in high-pressure dam and hydropower systems.

→ Series 1410 tilting disc check valves, type RA

Recoil check valves

AVK multi-door recoil check valves are available up to DN1600, and for pressure ratings up to PN25. They are cast in ductile iron with gunmetal seat and are designed for surge-critical applications, ideal for protecting pumps and pipelines in dams, reservoirs, and hydropower facilities.

→ Series 641 multi-door recoil check valves

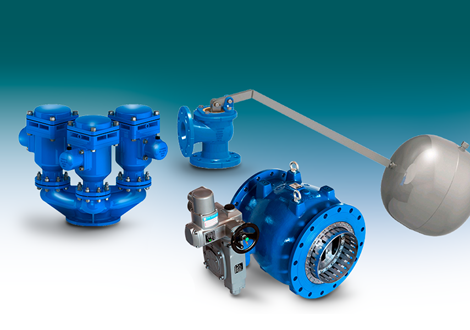

Regulating valves

In complex water systems like dams and hydropower plants, regulating valves and air valves support safe and efficient operation of the system. For high-pressure and/or critical flow regulation, needle valves offer accurate throttling by virtue of their near linear flow characteristic, making them ideal for turbine bypasses and bottom outlets.

Needle valves (plunger valves)

AC.MO needle valves, available up to DN1600 and PN40 as standard, are designed for throttling and control of pressure and flow at high flow rates and high differential pressures. The focus is on durability and reliability with the sturdy valve housing made of stainless steel up to DN150 and ductile iron coated with fusion bonded epoxy in larger sizes. They are ideal for turbine bypass and bottom outlet duties in dams and hydropower systems.

→ Series 872 needle valves

Ball float valves

AVK ball float valves are designed to be fitted in the top of a tank or reservoir to automatically control the rate of filling and shut off completely when a predetermined level is reached, and are ideal for maintaining safe water levels in smaller reservoir installations. The balanced equilibrium design makes sure that operation is smooth and reliable. They are cast in ductile iron with lever and float of ABS or stainless steel and available in DN50-300.

→ Series 854 ball float valves

Air valves

Air valves protect pipelines by automatically releasing trapped air during filling and allowing sufficient air into the pipeline to prevent a vacuum forming behind a disc, needle/plunger or gate closing into a high velocity flow, or during pipeline drainage. If a vacuum is allowed to form, then damaging downstream cavitation or even pipe collapse can occur.

AVK double orifice cluster arrangement air valves with VNR function are designed for reliable air release and vacuum prevention in water pipelines up to PN16. They allow air to enter the pipeline freely on separation but controls the expulsion as the column rejoins. This creates an air buffer that effectively reduces the impact velocity and the surge potential of the system. The second orifice automatically discharges accumulated air during normal working conditions. They are cast in ductile iron with all other components in polymer material or stainless steel.

→ Series 851 air valves

Dismantling joints

Dismantling joints facilitate easy installation and removal of flanged pipes, valves, pumps, and other equipment. They allow axial adjustment during assembly and disassembly, thanks to their telescopic design. We offer two main configurations, see more details:

- Central flange design with tie rods ensuring high strength and tight sealing, available in various configurations and up to DN2600 and PN25

- Compact two-flange space-saving design with fewer tie rods, available in mild steel up to DN1600 and PN16